The efficiency and reliability of product movement are vital in all industries, including manufacturing and packaging, as well as electronic and cleanroom processes. Conveyor systems are prominent in ensuring a consistent workflow, reducing human efforts, and enhancing overall productivity.

But there are no two industries that work alike, and every industry needs a conveying solution that is suitable for its unique processes, materials, and environmental conditions. This is why customization is such a significant consideration.

A conveyor system that is designed to meet the specific needs of an industry would guarantee enhanced performance, enhanced safety, and easier integration with other equipment. Conveyor systems can be designed to accommodate any workflow through the provision of flexible design features, adaptable structures, and specialized components.

The following article describes how the systems may be tailored to suit the needs of varying industries and generate efficient, reliable, and well-coordinated material flow.

1. Customize Core Layout with Modular and Adjustable Design

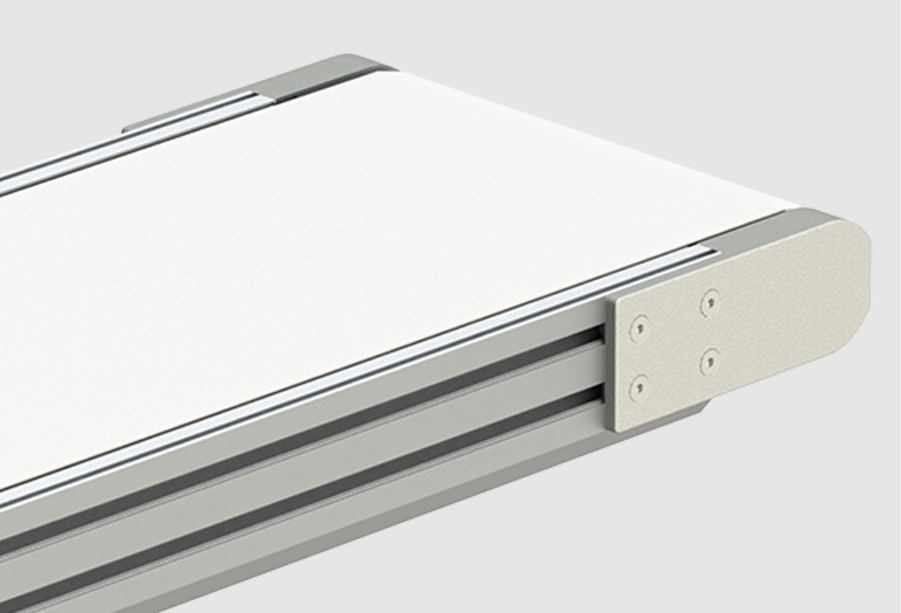

Most companies prefer conveyor systems with a modular solution since this type of design enables them to create designs that suit their workflow precisely.

With modular construction, the businesses will be able to mix various frame widths, belt types, and conveyor lengths to achieve an optimal path to fit their spaces and product dimensions. Moreover, this structure allows the incorporation of new parts or the elimination of parts, or the redesign of the line, considering the changes in operations.

Consequently, organizations have the benefit of a flexible foundation, which may be expanded according to their production needs without having any problem of transitioning between one step and another.

2. Adapt Drive Options, Speeds, and Load Capacities for Specific Tasks

Going ahead, industries tend to require different performance levels based on the materials in use. Thus, the personalization of the drive mechanism becomes a significant step.

The conveyor drives may be positioned at any location, depending on space, and various motor strengths support lightweight and heavy loads. Moreover, adjustable speed controls permit operators to have a constant speed that is like other processing equipment.

Such customization guarantees product movement stability and prevents bottlenecks, which is especially important in industries with timelines of high rigidity.

3. Enhance Product Handling with Tailored Accessories and Support Features

Moreover, the incorporation of conveyor accessories is significant in ensuring that every system is appropriate in its operation.

A great number of materials need guiding components, including side rails or containment functions, which hold products in place during transit. Height-adjustable stands, special mounting brackets, and protective covers also contribute to the control of various production conditions.

Through these elements, businesses obtain a secure and more regulated handling procedure, which eventually minimizes product harm and enhances workflow uniformity.

4. Select Materials and Design Elements for Industry-Specific Conditions

Besides structural customization, industries also tend to need conveyors that fit specific environmental or regulatory requirements. For example, food and packaging processes tend to require smooth surfaces and materials that are easy to clean. Similarly, cleanroom facilities require low levels of emission and controlled manipulation to avoid contamination.

On the other hand, electronics manufacturing might need belts that do not produce any static or those that help with fragile products with precision.

Through customization of belt materials, frame finishes, and general design, each system can be shaped to fit the specific conditions in which it will be used so that compliance and reliable performance can be achieved.

5. Integrate Conveyors Seamlessly with Automated and Multi-Stage Systems

As industries continue shifting toward automation, customized conveyor integration becomes even more important. By connecting conveyors with lifting units, transfer modules, or routing components, companies create a continuous flow that requires minimal manual intervention.

This integrated approach allows products to move through several stages—such as assembly, inspection, and packaging—without disruption.

Moreover, these modifications support faster throughput and more accurate positioning, which ultimately increases productivity across the entire operation.

6. Customize Structural Form and Orientation to Fit Space and Layout Limitations

Additionally, many facilities operate within limited floor space or have complex layouts that require unique conveyor arrangements.

To accommodate this, systems can be built with incline or decline paths, compact frames, curved sections, or multi-level structures. These options make it possible to route materials through tight corners, around existing machinery, or between elevated workstations.

By creating a conveyor system that fits harmoniously within the facility, operations maintain a steady flow without needing major structural changes, which is both cost-effective and operationally efficient.

7. Tailor Control Features, Sensor Technology, and Automation Settings

Finally, the control technology behind a conveyor can be customized to match the precision required in various industries.

By integrating sensors, automated monitoring, and adjustable speed programs, companies gain greater oversight of product movement. These features allow conveyors to respond to changes in workflow, detect product positioning, and maintain timing with other equipment.

As a result, material handling becomes smoother and more accurate, ensuring that the system supports both simple and highly detailed production tasks.

Conclusion

Customization plays a vital role in turning a standard conveyor into a system that genuinely supports an industry’s unique needs. By adjusting the structure, selecting appropriate materials, enhancing controls, and integrating automation, companies gain solutions that fit seamlessly into their workflows.

Customized conveyors provide stronger performance, reduce manual handling, and adapt effortlessly to production changes. As industries continue to evolve, the ability to shape these systems around specific processes remains essential for long-term efficiency and reliable daily operations.