A lot of teams buy a maintenance tool the same way they buy office software. They compare feature lists, pick a vendor, and hope adoption happens on its own. Then reality hits. Techs skip the app, data stays messy, and the “system of record” becomes a place where work orders go to die.

A better approach starts with clarity. Good CMMS software makes maintenance easier to run, easier to audit, and easier to improve. It also has to fit the way your sites actually work. That includes tools that tightly integrate with parts inventory software, so the right items show up at the right time with fewer surprises.

Start With Workflows, Not Features

Before demos, map how work moves today. From request to approval, from scheduling to close-out, from “we fixed it” to “we learned something.” If that map feels chaotic, even a great platform will inherit the chaos.

Spell out the daily actions that matter. Who creates a work order? Who approves it? How a tech gets assigned. What “done” means. Then match the system to that flow. The goal is not a long checklist. The goal is a tool that matches real habits, with minimal friction.

One practical tip: pick three typical jobs and walk through them end to end. A reactive repair, a planned preventive task, and an inspection. If the tool makes those three jobs simpler, you are on the right track.

Data Quality and Structure Decide the Outcome

A CMMS can only be as smart as the data you feed it. Asset names, locations, failure codes, meter readings, task notes. If those fields are inconsistent, reports will mislead you. Then people stop trusting the system.

Start small and structured. Define naming rules for assets and locations. Choose a short list of failure codes that people will actually use. Standardise the close-out notes. One sentence that explains what failed and what was done. Every time.

I once watched a team argue over “Pump 3” for twenty minutes because three different assets had that nickname. After we fixed the naming and location rules, the confusion vanished. Same equipment. Same staff. Cleaner data. Huge difference.

Inventory, Purchasing, and Kitting Matter More Than You Think

Many CMMS rollouts fail because parts are treated as afterthoughts. In practice, parts drive downtime. A work order can be perfect on paper, yet it still stalls if a seal kit is missing or a part is “in stock” but cannot be found.

Look for inventory tools that support how maintenance actually consumes parts. Minimums and re-order points. Part-location tracking. Issue-to-work-order logging. Simple receiving. And the ability to build kits for common jobs.

Also, check how purchasing works. Can you tie parts to vendors and lead times? Can you flag substitutes? Can you see the spending by asset class? These are not “nice-to-haves.” They remove delays and stop repeat emergencies.

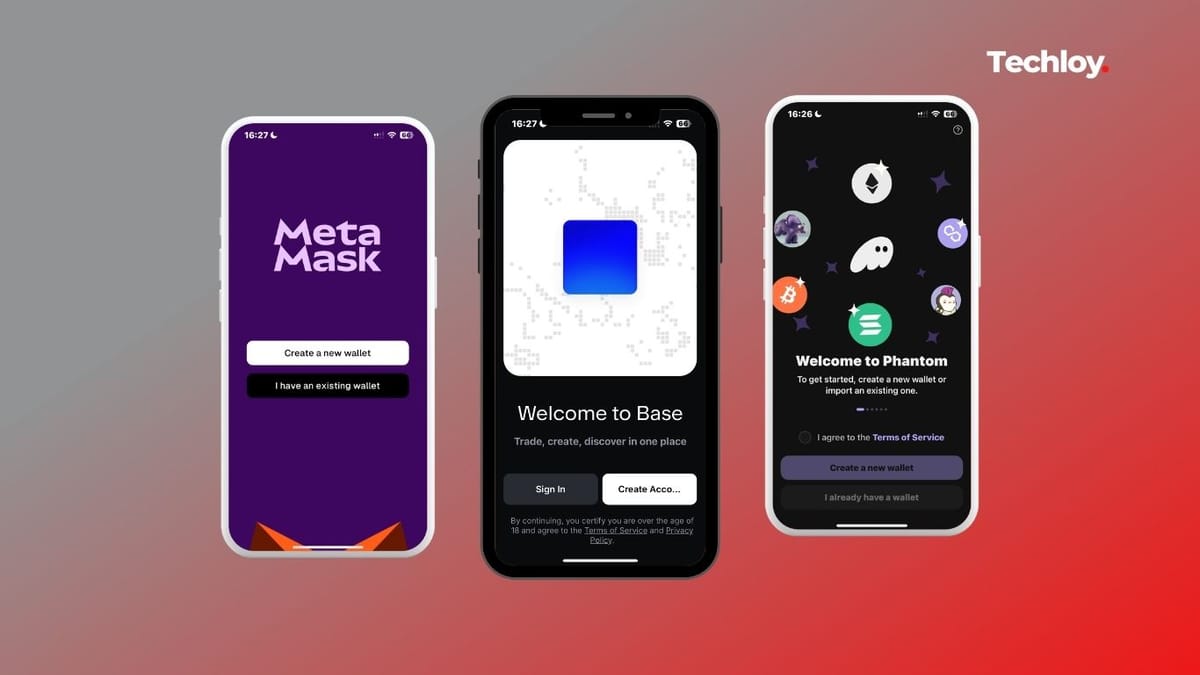

Mobile Use and Adoption Are the Real Make-or-Break

If techs avoid the tool, the project is already lost. That is why mobile matters. The app should load fast, work in a weak signal, and make updates easy with gloves on.

Focus on the basics. Can a tech view assignments, open an asset, read past notes, add photos, and close the job in under a minute? If every step feels slow or cluttered, usage will drop.

Adoption also needs a setup that respects time. Short training, clear rules, and a few champions on each shift. Keep it practical. Nobody wants a lecture. People want fewer headaches.

Security, Scale, and Systems Fit

For a technology audience, this is where scrutiny rises. Ask how the platform handles role-based access. Audit logs. Single sign-on. Backups. Data export. These are the guardrails that keep operations stable.

Then look at the scale. Multi-site support, asset hierarchies, and location-based permissions. If you plan to grow, the CMMS should grow without becoming a new problem.

Finally, think about system fit. The CMMS must play well with your accounting, procurement, and reporting stack. Even without deep connectors, clean exports and stable APIs can be enough. The key is predictable data, in predictable formats.

To Conclude. Choose the Tool That Makes Daily Work Easier

A smart CMMS choice is less about feature count and more about fit. Fit to your workflow. Fit to your data discipline. Fit to your inventory reality. Fit to your team’s daily pace.

Keep your selection process grounded. Test real jobs in a demo. Involve techs early. Validate inventory and mobile steps. Confirm security and scale with the same seriousness you would use for any enterprise tool.

Then commit to a clean setup and steady adoption. Small wins first. Clear rules. Consistent use. That is how a CMMS becomes a trusted system, instead of another tab people ignore.