3D printing has overhauled several sectors, but perhaps the most significant changes have come in the manufacturing industry. Manufacturing has grown from fast prototypes to full production.

So, it is no surprise that the industry has gone all out when it comes to automation. After all, the demand for scalability and efficiency is overwhelming in this sector. One clearly successful development is the evolution of multi-plate automation systems.

Over the past 10 years or so, incredible innovations have made multi-plate automation accessible to large manufacturers and small-scale operators. As such, both have been able to expand their printing operations.

But let’s look back at where and how 3D printing started, as well as how we got to where we are today.

Early 3D Printing

The first commercial 3D printers were developed in the 1980s. Stereolithography in the 80s and fused deposition modeling in the 90s allowed for layer-by-layer printing.

However, each printed part had to be removed manually before a new build plate could be set up. This process was suited to prototyping but did not support high productivity or continuous printing.

In the early 2000s, 3D printing expanded industrially. Manufacturers needed to find a way to reduce the downtime between prints. The first steps toward multiple plates came in the form of stackable plates and semi-automated handling.

These systems allowed operators to prepare more than one plate ahead of time. Still, full automation was not realized, and the process needed constant supervision.

Multi-Plate Automation

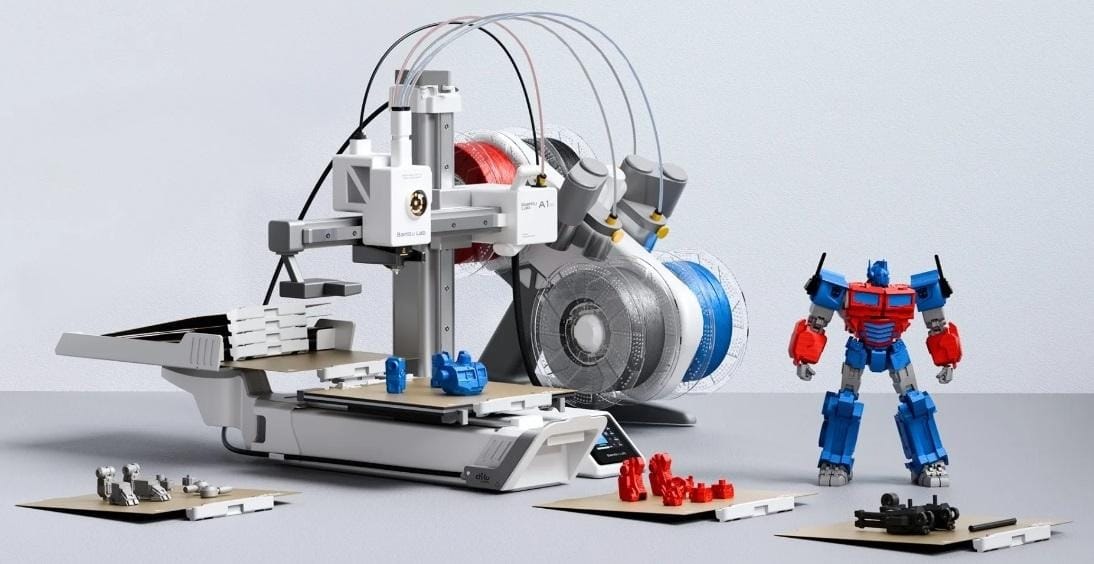

A multi-plate system was the answer to the full automation issue. These systems address bottlenecks that arise when plates are changed manually. Multiple build plates in a single printer means the system can automatically swap a completed print for a fresh plate, allowing for continuous operation.

Early multi-plate systems were designed primarily for industrial environments. They involved large robotic arms and conveyors. Some also included gantry systems. The aim was to handle heavy plates and large-format prints.

Multi-plate systems dramatically increased production throughput. They enabled 24/7 production with only minimal human supervision.

As the technology quickly matured, engineers adapted multi-plate automation for smaller-scale printers. Compact systems focused on desktop and benchtop printers with lighter build plates. These setups retained the core benefits of automated plate swapping, but they were designed to fit in a limited space. They could also operate quietly in offices or laboratories.

Multi-Plate Automation Components

Today, multi-plate automation in industrial and small-scale operations relies on several components:

- Automated plate handling. Systems use mechanical mechanisms to move the build plates in and out of the print area. Large manufacturers use gantries and robotic arms. Small-scale systems use rotating platforms or linear actuators.

- Sensors and feedback. The sensors in the system detect the position of the build plate. They ensure that each swap is done properly and precisely. For small printers, compact sensors maintain accuracy without needing bulk.

- Software. Automation software can help schedule print jobs. This software can also monitor print progress and coordinate plate swaps. Advanced software prioritizes jobs based on material, print time, and urgency.

- Safety and reliability. Automated systems include safety interlocks and error detection. In a small-scale setup, these features ensure the system can operate unsupervised without damaging the printer.

Advantages of Multi-Plate Automation for Small-Scale Printing

The advantages of this 3D innovation are not only evident in industrial sectors. Small-scale systems see several benefits, too:

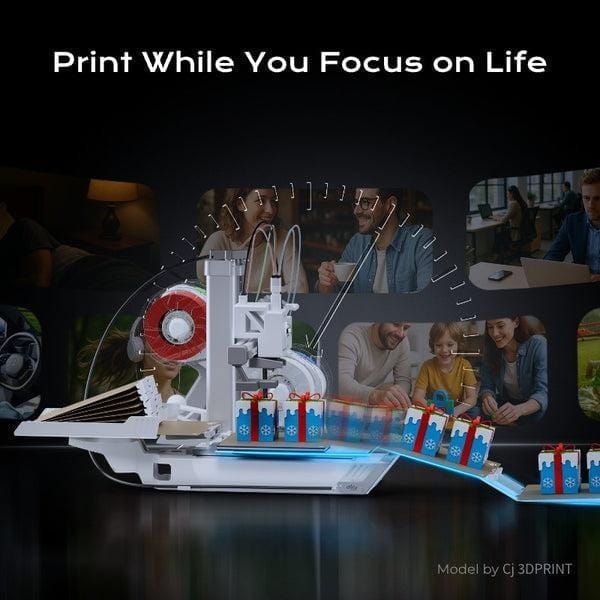

- Continuous operation. Small-scale printers with automated plate swapping can run multiple prints consecutively. This process does not need operator intervention.

- Improved workflow. Automation allows operators to focus on design and post-processing. It also allows for a greater focus on quality control rather than on manual handling of build plates.

- Flexible scheduling. Multi-plate systems can prioritize prints of different sizes or materials. This accommodates mixed-material projects and small batches.

- Better print consistency. Automated systems reduce the risk of errors caused by manual plate handling. It also improves print quality and makes it easier to repeat prints in compact printers.

Industrial and Small-Scale Adaptation

In an industrial context, multi-plate automation helps improve high-volume production. Fully automated print lines run every day, producing dozens of parts in the aerospace, automotive, and medical device manufacturing industries.

Large plates and heavy materials require precise coordination with post-processing workflows.

In small-scale printing, the focus moves from raw volume to efficiency. Compact automation solutions make fast prototyping easier. It also moves along the design cycle and keeps low-volume production going without intervention.

Schools and universities, as well as research labs, benefit from this. Automation means these institutions can experiment with running simultaneous projects while saving time and resources.

Challenges to Consider

As with any type of innovation and technology, there are some challenges to look out for with multi-plate innovation.

- Cost. Even compact automation systems will likely require a higher upfront investment compared to manual plate handling. Companies and 3D enthusiasts should weigh the costs against their production needs.

- Compatibility. It is important to note that not all 3D printers are designed for automated plate swapping. Mechanical and software compatibility is crucial for integration.

- Maintenance. Automated systems must be checked and maintained to prevent failures. Even small-scale systems need proper maintenance for reliable performance.

- Training. Some training is required so that operators know how to manage the printer and plates. In small-scale setups, users may need to learn basic troubleshooting.

Recent Innovations

Ongoing innovations continue to make multi-plate automation more accessible, especially to small-scale printers.

- Lightweight plates. Lighter materials reduce mechanical stress.

- Rotating and modular platforms. Small printers can use rotating platforms or modular racks to store multiple build plates.

- Automated job queues. Modern software can automatically sequence print jobs across multiple plates.

- Integration with remote monitoring. Operators can monitor and control printing and plate swaps via apps.

Linking Efficiency and Accessibility in 3D printing

Multi-plate automation was once a niche industrial tool. It is now a versatile solution for large and small-scale 3D printing. Multi-plate systems reduce manual intervention. They improve throughput and increase consistency. These are crucial in applications such as aerospace components and prototyping in research labs.

As technology continues to improve, there will be even more integration of automation. With the help of artificial intelligence and adaptive workflows, multi-plate systems will continue to be central to additive manufacturing at all scales.